Recently, Professor Xiaodong Wang from Shanghai Jiao Tong University, in collaboration with Professor Huabing Li from Northeastern University and Professor Mingwei Chen from Johns Hopkins University, made significant progress in the field of high-nitrogen stainless steels. The research article, "Martensitic transformation induced planar deformation of AlN nanoprecipitates in high nitrogen stainless steels", was published in the internationally renowned academic journal “International Journal of Plasticity” (Publication link:https://doi.org/10.1016/j.ijplas.2023.103631).

Prof. Xiaodong Wang, Prof. Huabing Li from Northeastern University, and Prof. Mingwei Chen from Johns Hopkins University are the corresponding authors of the article. Zhang Yumeng and Hu Yixuan, both PhD students at Shanghai Jiao Tong University, are the co-first authors of the paper. The research work has been supported by Prof. Yipeng Gao from Jilin University, Prof. Yao Shen from Shanghai Jiaotong University and other collaborators, as well as the National Natural Science Foundation of China (No. U1960203, 51971135, 52171010, 51821001).

Metallic materials with both high strength and high ductility have been highly sought after in lightweight structural applications, among which the development of gigapascal-level high-strength steel has been a hot research topic. High-nitrogen martensitic stainless steel, as one of the most competitive resource-saving steel grades, is widely used in aerospace bearings, cutting tools, and marine applications due to its ultra-high hardness/strength and excellent fatigue and corrosion resistance properties. Under severe service conditions of high impact stress, high temperature, and corrosive environment, premature failure is often caused by fatal inclusions or harmful precipitates such as Al2O3, AlN, and TiN. The hard and sharp AlN precipitates easily formed between residual Al and added N elements in the steel can cause local stress concentration and induce microcracks. The strict requirement for Al content in the steel poses great challenges to raw materials and processing costs.

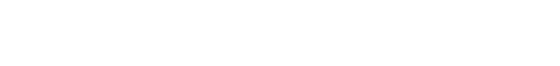

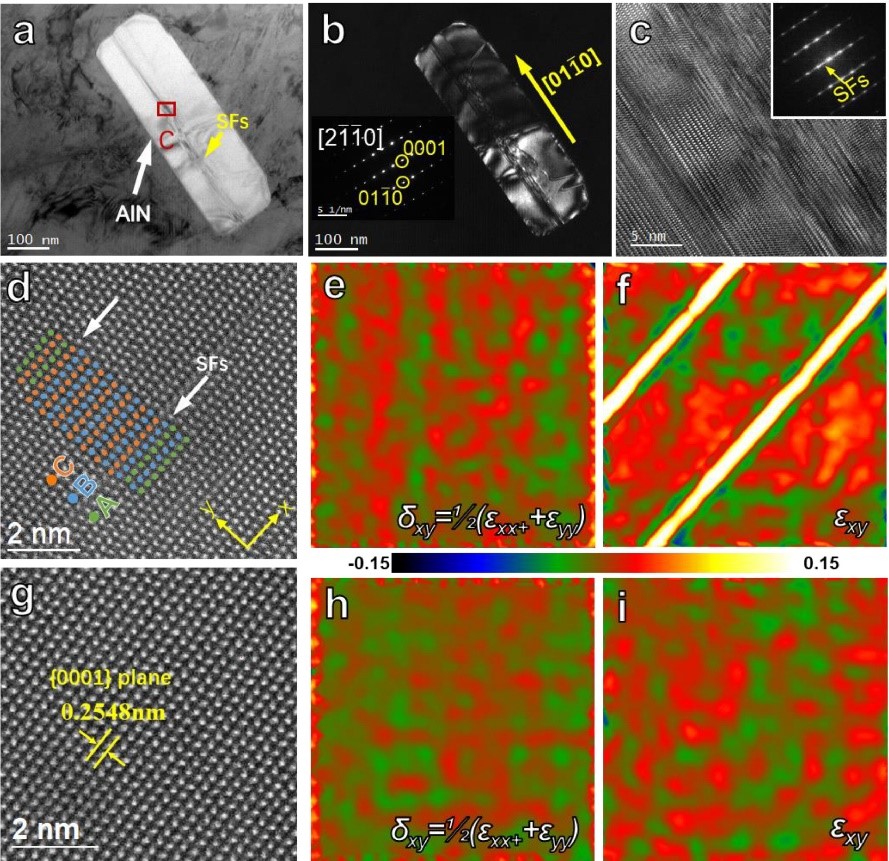

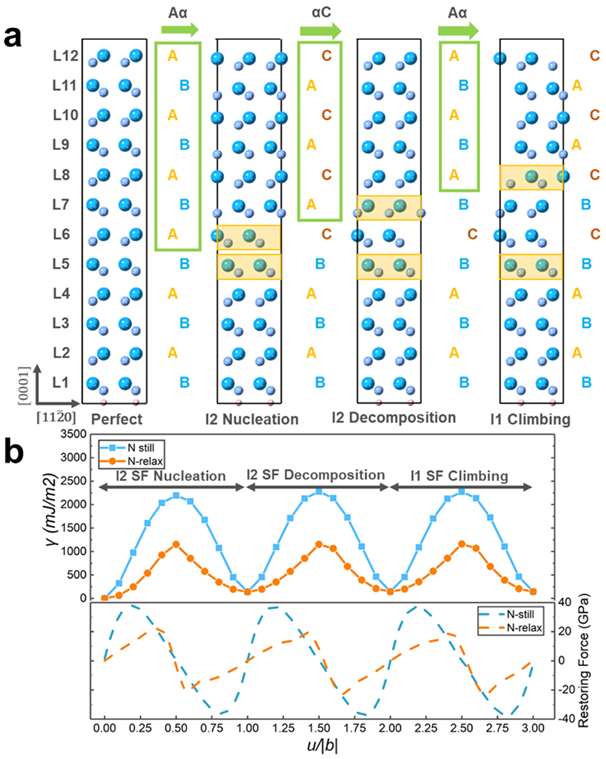

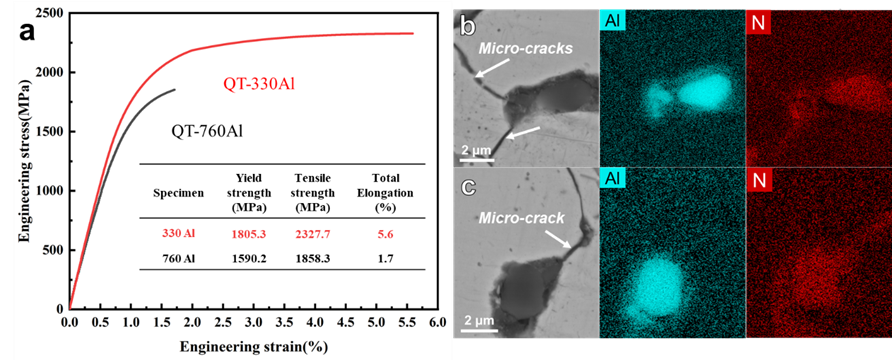

Previous studies on AlN, a typical hard covalently bonded ceramic material, have focused on the thermodynamics and kinetics of AlN precipitation in steels and its functional properties as photoelectric device materials. However, the deformation behavior of AlN precipitates and their interaction with the steel matrix have not been revealed. Herein, the stacking faults-assisted planar deformation mode in AlN nanoprecipitates was observed for the first time, which is a rare phenomenon in materials with high stacking fault energy (Fig. 1). Through density functional theory and phenomenological theory of martensitic crystallography, it is proved that the plastic deformation of AlN is activated by the martensitic transformation of martensite (Fig. 2). Furthermore, atomic-scale strain analysis showed a localized high stress/strain at the interface between AlN and the martensitic matrix which was induced by the martensitic transformation (Fig. 3). The plastic deformation assisted by stacking faults in AlN nanoprecipitates can alleviate the strain compatibility conflict, improve the processing and comprehensive performance of high-nitrogen steel, and prevent premature failure of the martensitic steels (Fig. 4).

The findings have increased the upper limit of Al residue to a level comparable to normal steelmaking, thus expanded the process window for high-nitrogen steel production. This may pave a new way to mitigate the harmful effect of AlN precipitates and to reduce the production costs

Fig. 1 S/TEM characterization and strain distribution maps of AlN in QT-330Al high-nitrogen martensitic stainless steel

Fig. 2 First-principles simulation study of the generation process of dislocations

Fig. 3 Strain distribution inside the martensite matrix near the AlN precipitate

Fig. 4 The effect of AlN nanoprecipitates on the mechanical properties of high-nitrogen martensitic stainless steel