Recently, the research team of Professor Hua Xueming and Associate Professor Shen Chen from the Institute of Welding and Laser Manufacturing at Shanghai Jiao Tong University collaborated with Fuzhou University to publish the latest research "Effect of variable polarity during cold metal transfer on microstructure and mechanical properties of directed energy disposal arc build 2209 duplex stainless steel" in the journal "Additive Manufacturing" (Impact Factor: 11). This paper applies the variable polarity cold metal transfer (VP-CMT) mode with lower heat input to the DED-arc process, further reducing heat accumulation and austenite phase ratio.

Paper Link: https://doi.org/10.1016/j.addma.2023.103750

Research Background

Duplex stainless steel (DSS) is recently considered as a promising candidate to replace traditional bronze-based alloys in medium to large sized ship propellers, due to its combination of advantages including excellent specific strength and corrosion resistance. Directed energy deposition-arc (DED-arc) is chosen as the preferred method to make ship propellers because of its flexibility and high efficiency. However, excessive austenite is formed in the DSS deposits due to severe heat accumulation caused by DED-arc process, which greatly limits the mechanical properties of DSS. Therefore, arc process with lower thermal accumulation effects is crucial for achieving a more ideal phase ratio of DSS deposits.

Research Content

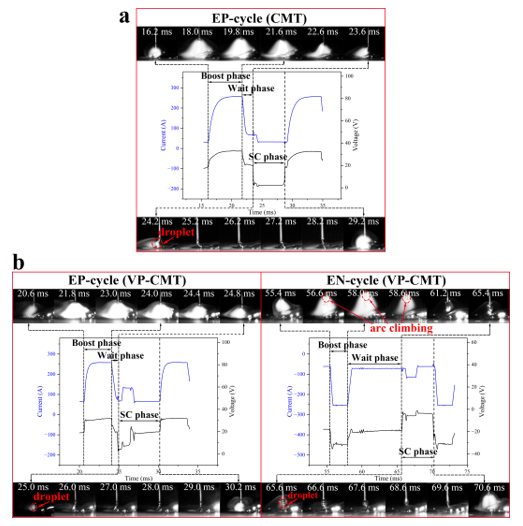

This paper confirmed the effectiveness of VP-CMT mode in decreasing austenite volume fraction in both as-deposited and reheated zones, therefore under the same wire feed and travel speeds, VP-CMT produces higher strength DSS components than normal CMT. Also, the lower line energy input of VP-CMT leads to smaller reheated zone in DSS buildup walls, such morphology difference further induces larger tensile property anisotropy than normal CMT sample. VP-CMT shows more potential in controlling the ferrite/austenite ratio to equilibrium than normal CMT.

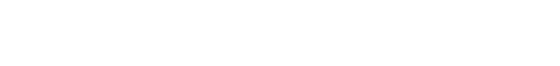

Fig. 1. Macrography of buildup walls. (a) YOZ section of CMT wall, (b) XOZ section of CMT wall, (c) YOZ a section of VP-CMT wall (d) XOZ section of VP-CMT wall

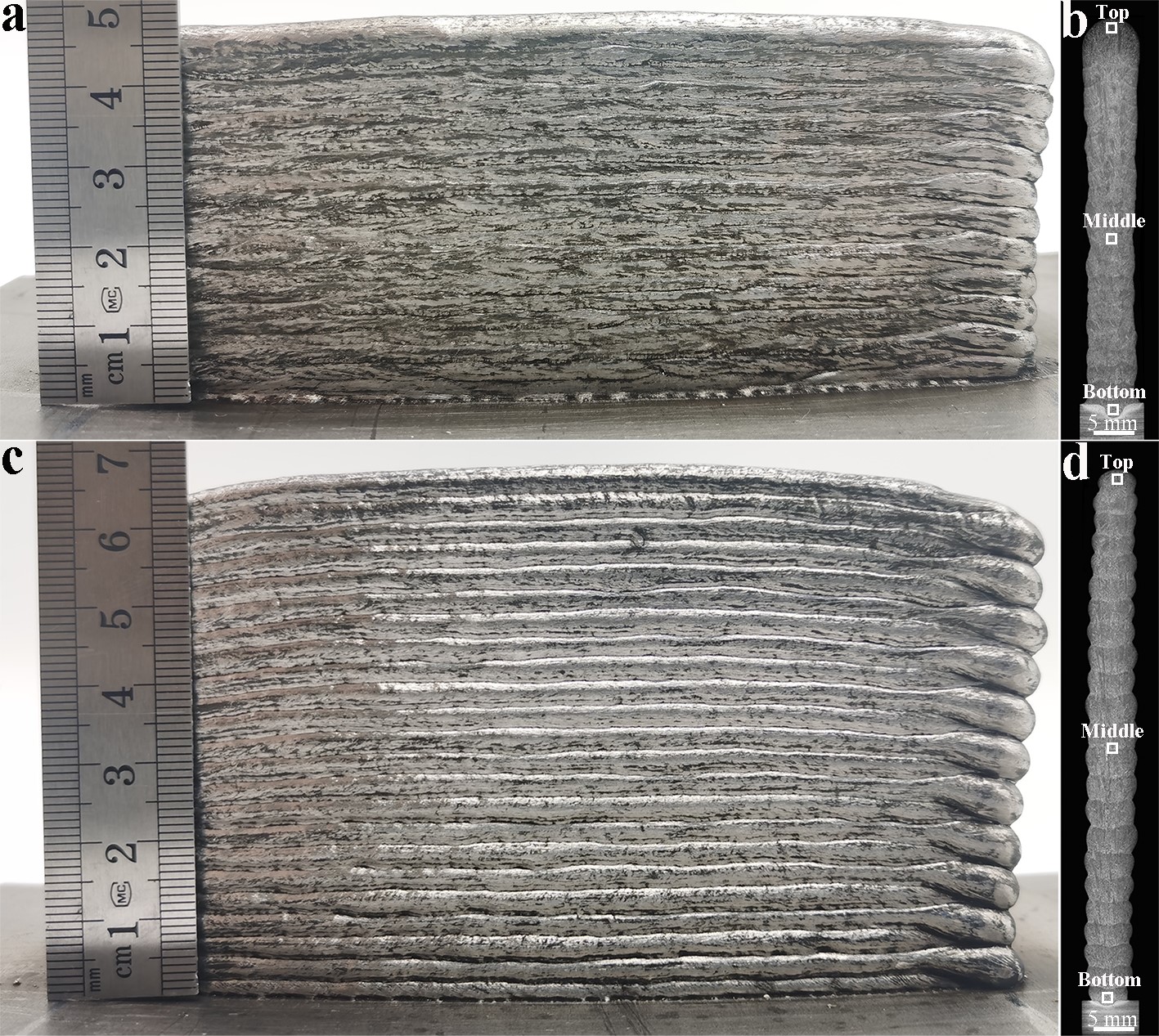

Fig. 2. The arc and droplet transfer behaviors (a) CMT, (b) VP-CMT

Fig. 3. Phase maps of the middle part of the buildup walls. (a) CMT DED-arc wall, (b) VP-CMT DED-arc wall

Fig. 4. Tensile properties of buildup walls. (a) tensile curves of specimens along vertical direction, (b) tensile curves of specimens along horizonal direction

Main Conclusion

1. The CMT deposition wall exhibits an austenite content of approximately 72.1%, whereas the VP-CMT deposition wall showcases a content of about 65.6%, signifying a reduction of 6.5%. This reduction can primarily be attributed to two factors: (1) a decrease in the proportion of austenite within the reheated zone and as-deposited zone in the VP-CMT buildup wall; (2) a reduced proportion of the reheated zone in the VP-CMT buildup wall.

2. By introducing variable polarity, the horizontal tensile strength of the buildup wall experiences a 3.3% increase in comparison to the CMT buildup wall, while the elongation endures a decrease of 5.1%. This result occurs due to the refinement of ferrite grains and a reduction in the proportion of the austenite phase. As for the vertical tensile strength, the VP-CMT buildup wall is on par with the CMT buildup wall, yet the vertical plasticity increases by 8.3%. This increase is due to the fact that the reheated zone within the VP-CMT buildup wall still retains a significant proportion of austenite, thereby rendering it the weaker zone. Furthermore, the VP-CMT deposits exhibit a greater extent of epitaxial growth of ferrite columnar grains and a decrease in small cellular ferrite grains with a deviation of <001> orientation, which can impede dislocation movement and deformation near the fusion line.

3. After the introduction of variable polarity on CMT process, the heat input is decreased. Because the EN-CMT cycles concentrated more energy on the filler wire, and the duration of boost phase is reduced.

4. Despite the VP-CMT process effectively reducing the proportion of austenite compared to the CMT process, achieving the desired phase ratio (50% austenite) remains challenging. Therefore, it is necessary to explore alternative methods beyond changing the power mode in order to fundamentally attain the optimal phase ratio in DED-arc deposits.

Corresponding Authors

Xueming Hua: Director, Professor, Doctoral Supervisor of the Institute of Welding and Laser Manufacturing at Shanghai Jiao Tong University, and Chairman of the 11th Council of the Shanghai Welding Society。Research directions:Welding Arc Physics and Advanced Welding New Methods, Laser welding and robot welding technology, wire arc additive manufacturing, etc. Published over 200 papers and authorized more than 30 national invention patents.

Chen Shen: Associate Professor, Doctoral Supervisor of the Institute of Welding and Laser Manufacturing at Shanghai Jiao Tong University. Research directions: wire arc additive manufacturing for metals and intermetallics, Characterization of Stress and Phase Transformation in Metal Materials by Neutron Diffraction. Published over 60 papers in international journals.

Paper Information

Wu K, Hua X, Shen C, et al. Effect of variable polarity during cold metal transfer on microstructure and mechanical properties of directed energy deposition-arc built 2209 duplex stainless steel[J]. Additive Manufacturing, 2023, 75:103750. https://doi.org/10.1016/j.addma.2023.103750